Problem

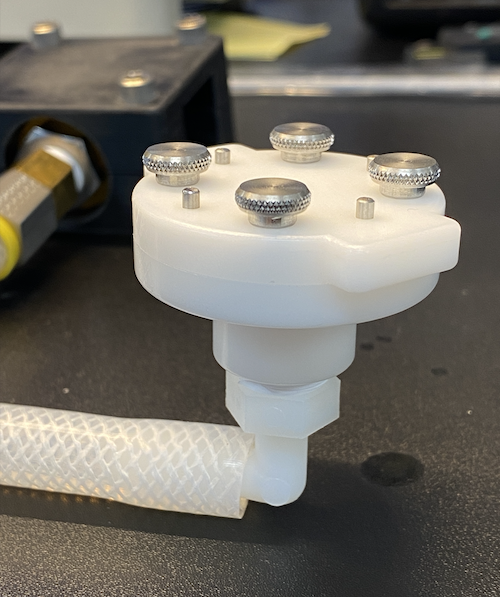

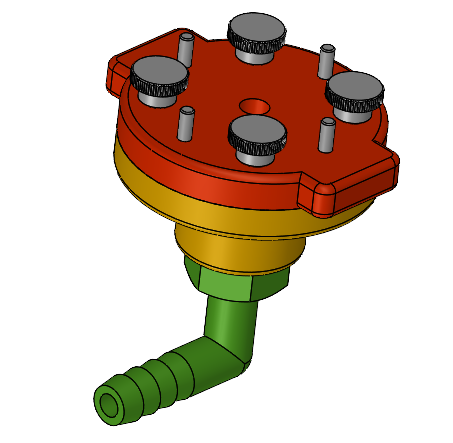

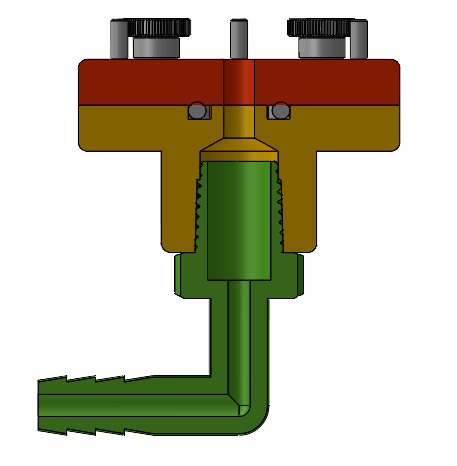

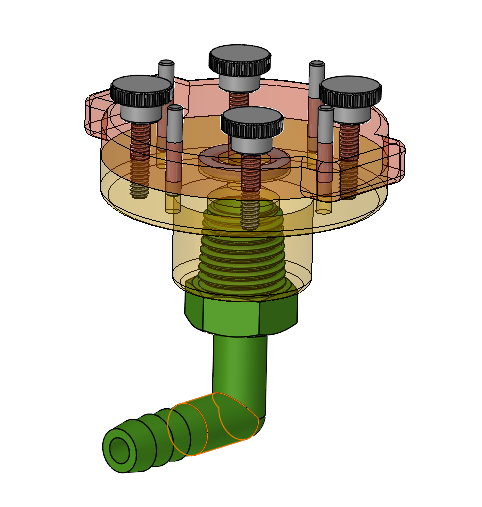

A component of one of the company's proprietary products required pressure testing to evaluate which specimen would provide the best air permeability results.

Objective

To design and develop a fixture that can easily, quickly, and accurately measure and test the rate of flow of air passing through a tested specimen under a vacuum seal.

Skills Employed

- SOLIDWORKS 3D CAD model and 2D drawings with tolerances

- 3D Printing SLA

- Machine shop manufacturing and tool use (tapping, drills, sanding)

- Working with vacuum seals, o-rings, dowel pins, thumbs screws, barbed fittings and tubings

- Testing fixture design/mechanical testing