Approach

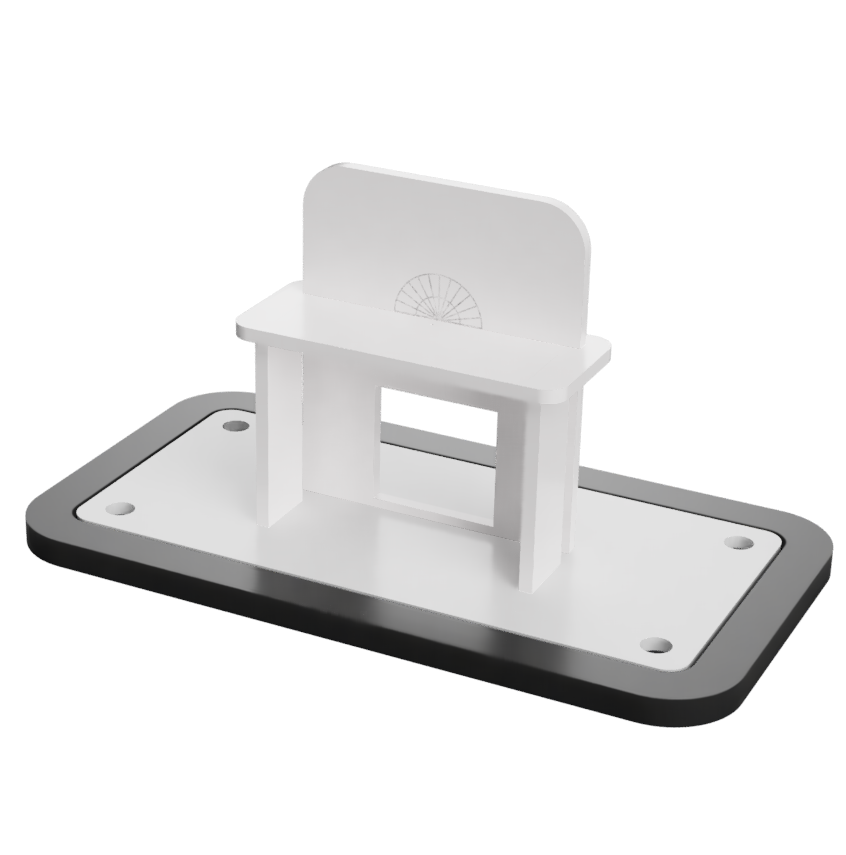

For this fixture, I created a CAD model using OnShape - render of the model shown in Figure 2. The fixture was a simple structure aimed to secure the bellows of the needle deployment system. The fixture incorporated a clearance hole for the needle tubing to slide through - this hole ensured that the tubing would not contact the plate and affect the bending of the system.

The back plate was designed with engravings using a CO2 Laser Cutter. The engravings were filled in with paint for a more pronounced look. The engravings were used to help calibrate and scale the system from captured images. In addition, the back plate was removable, and another backing plate for a diffferent test could be swapped in. For example, in Figure 3 an expansion ratio backing plate could be swapped in.

For blocked force testing, the bottom plate can be mounted onto an Instron, and the back plate can be removed.

Once the CAD model had been designed, the components were laser cut and assembled.

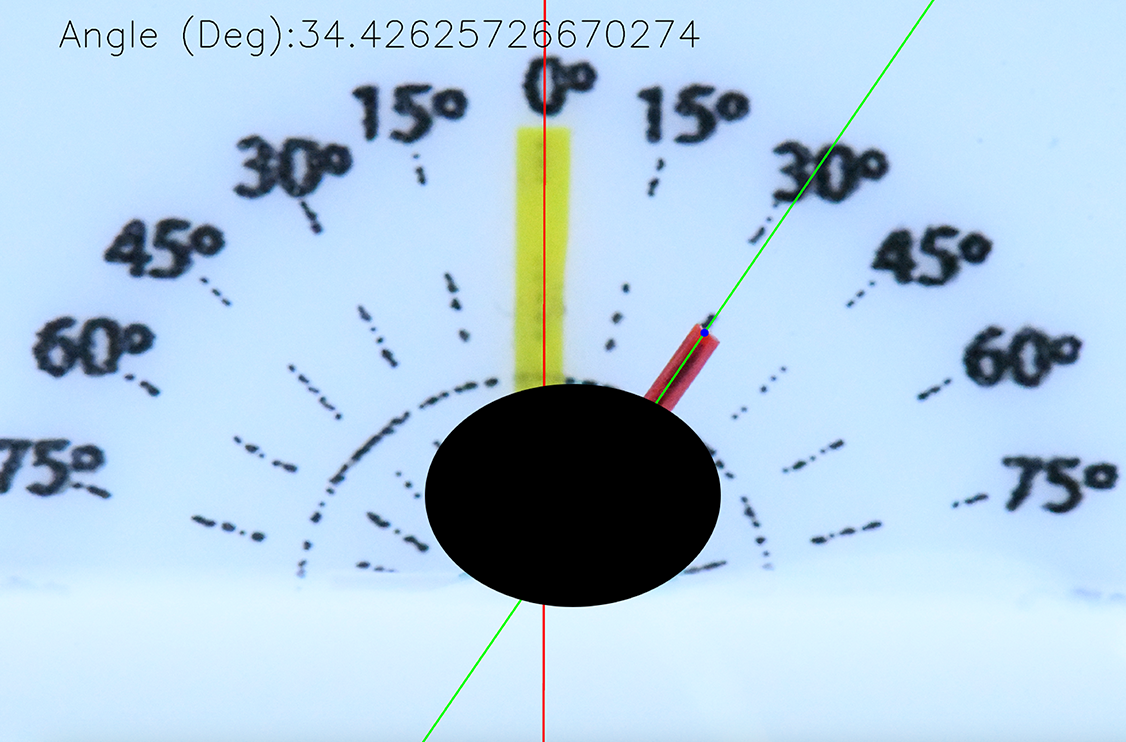

Image Processing Python Script for Automating Bending Calulations:

- This script could take in inputs of images captured from the bend test. The bend test pressurized the needle deployment system at various pressure

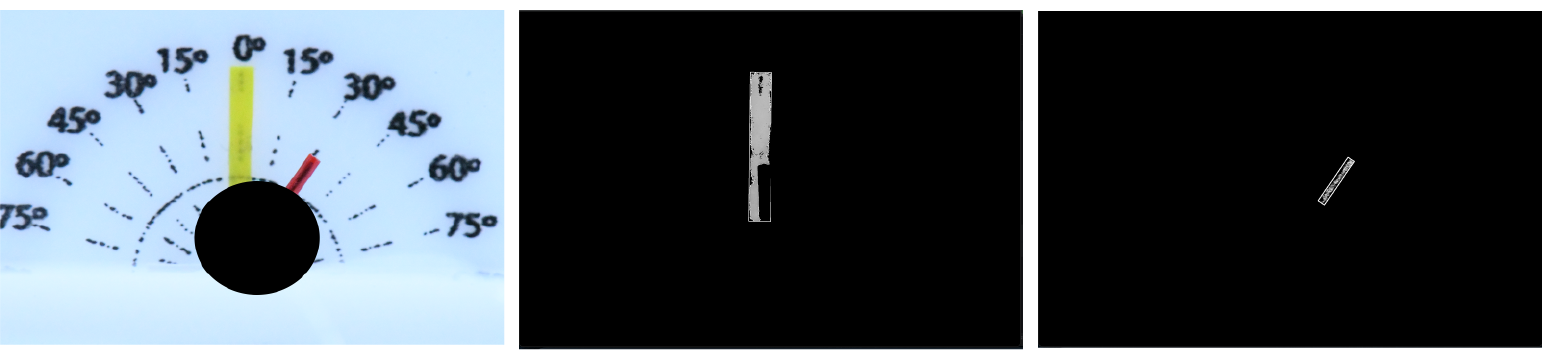

- By using thresholds, calculated the center line of the vertical reference line by isolating the color yellow, creating a bounding box around a contour, and drawing a centerline

- By using thresholds, calculated the center line of the needle on the needle deployment system by isolating the color red, creating a bounding box around a contour, and drawing a centerline

- Calculated the difference in angles (degrees) between the two centerlines

- Compiled the different bending angles and exported them to an excel sheet