Problem

During tensile testing, the samples can break at the grips - which is not a true measurement of the breaking strength of the material. A new method of securing the sample in the Instron grips must be created to measure the true breaking strength.

Objective

To design a new method of securing the sample in the Instron grips for tensile testing of the sample.

Skills Employed

- SOLIDWORKS 3D CAD model

- Technical 2D drawings with tolerances

- Documentation of fixture according to company’s protocols

- Testing fixture design/mechanical testing

- Instron Tensile Testing and Test Method Development

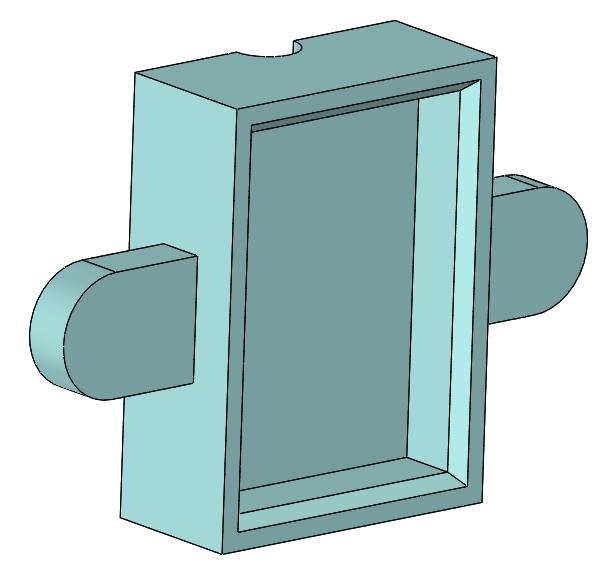

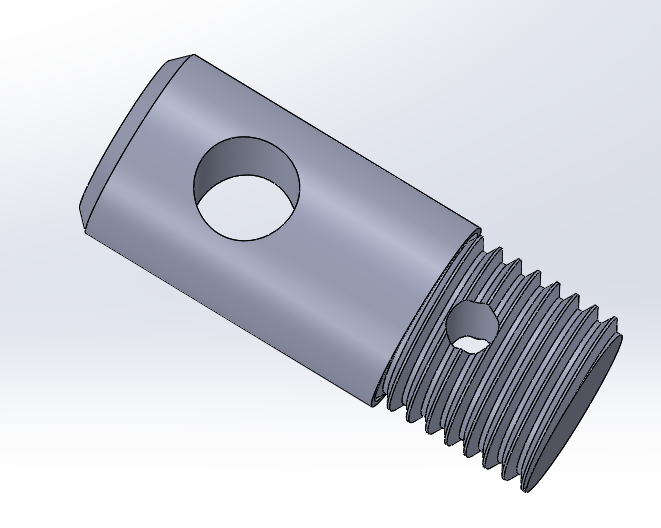

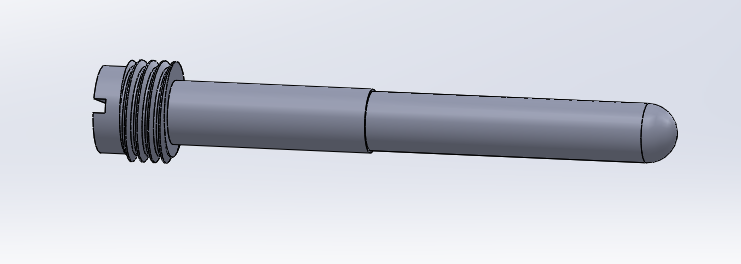

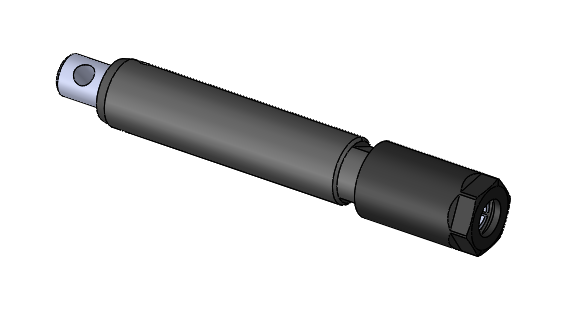

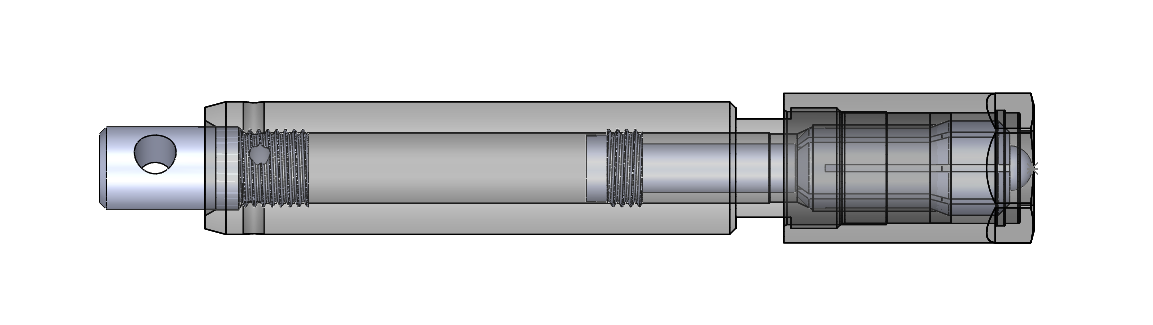

Figure 1. 3D CAD Model of Tensile Testing Fixture for Device