Problem

The company’s products required fixtures to stabilize each component during force measurement tests.

Objective

To create/update fixtures (inherited an older design from a colleage) for various force testing for design verification testing, including: an off-axis tensile test, a button compression test, and a torque test.

Skills Employed

- SOLIDWORKS 3D CAD model

- 3D printing - FDM and SLA

- Machine shop manufacturing and tool use (tapping, drills, sanding)

- Test method characterization and development

- Testing fixture design/mechanical testing

- Instron Tensile and Compression Testing

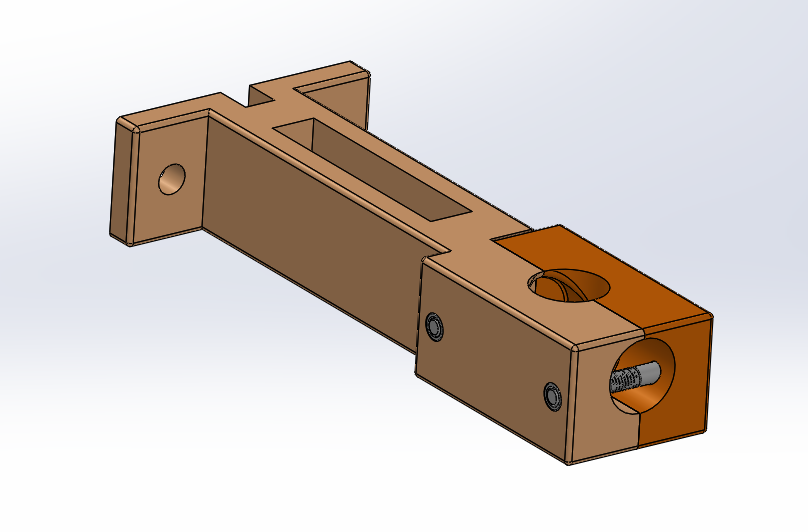

Figure 1. 3D CAD Model of compression testing fixture