Problem

Currently, many force testing on the Instron occurs at room temperature. Without access to an Instron Bath Attachment, there needs to be another method of performing force testing of samples in a heated bath environment.

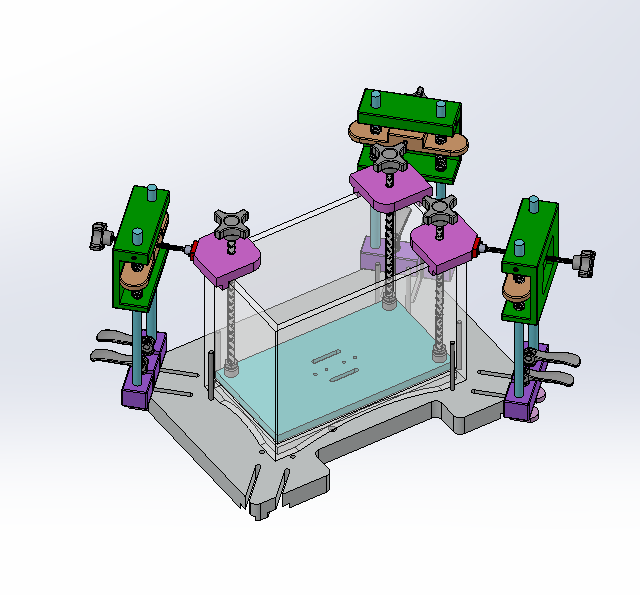

Objective

To design a method and fixture to secure a water tank to the base of the Instron and perform tensile and compression tests with it. The fixture must also be able to securely hold the water tank in place but also be easily removable.

Skills Employed

- SOLIDWORKS 3D CAD model

- 3D Printing (FDM)

- Machine shop manufacturing and tool use (tapping, drills, sanding)

- Testing fixture design/mechanical testing

- Instron Tensile Testing