Problem

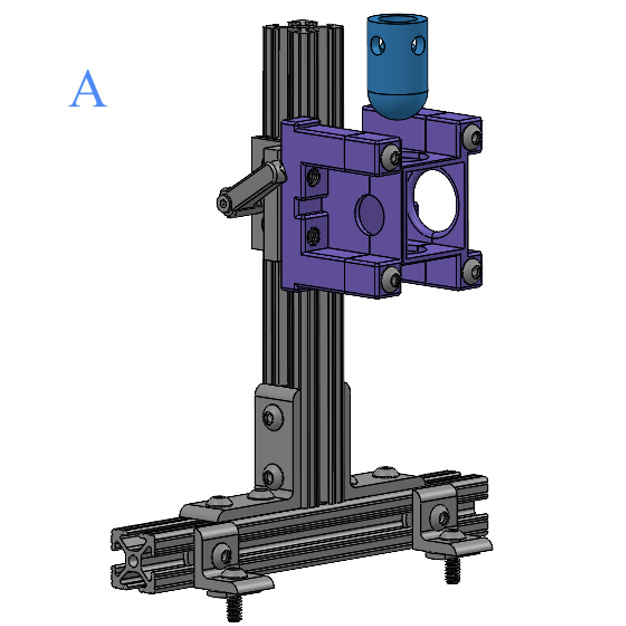

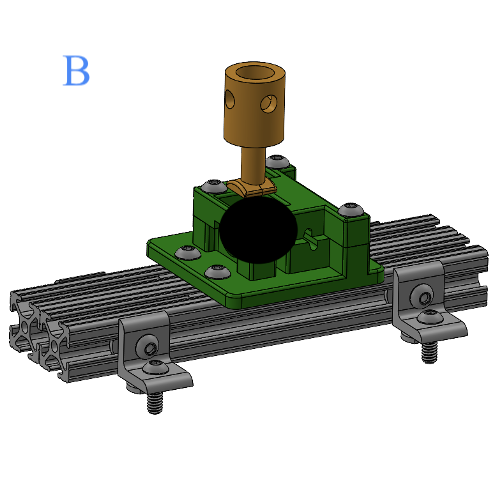

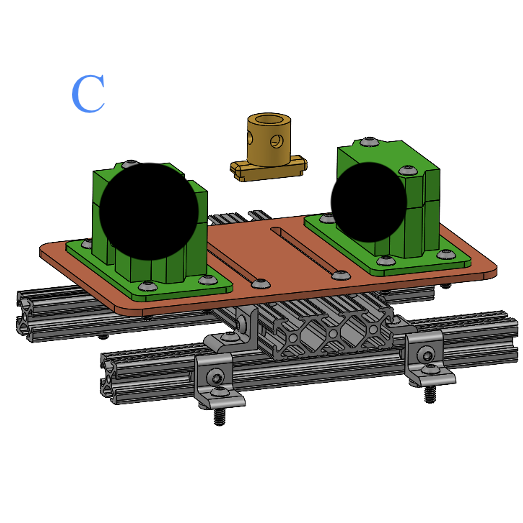

The company’s products required fixtures to stabilize and a method of actuation for each component during force measurement tests.

Objective

To design and develop fixtures and test protocols that can securely hold and smoothly actuate each component to accurately gather force measurement data.

Skills Employed

- SOLIDWORKS 3D CAD model and 2D drawings with tolerances

- 3D Printing FDM

- Laser Cutting

- Working with 80-20 rails, linear bearings, structural brackets, fasteners

- Snap-fits and cavity designs

- Machine shop manufacturing and tool use (chop saw, tapping, drills, sanding)

- Working with heat set and press fit inserts, ACME lead screws, thumbs screws, set screws

- Chatillon Force Measurement

- Testing fixture design/mechanical testing

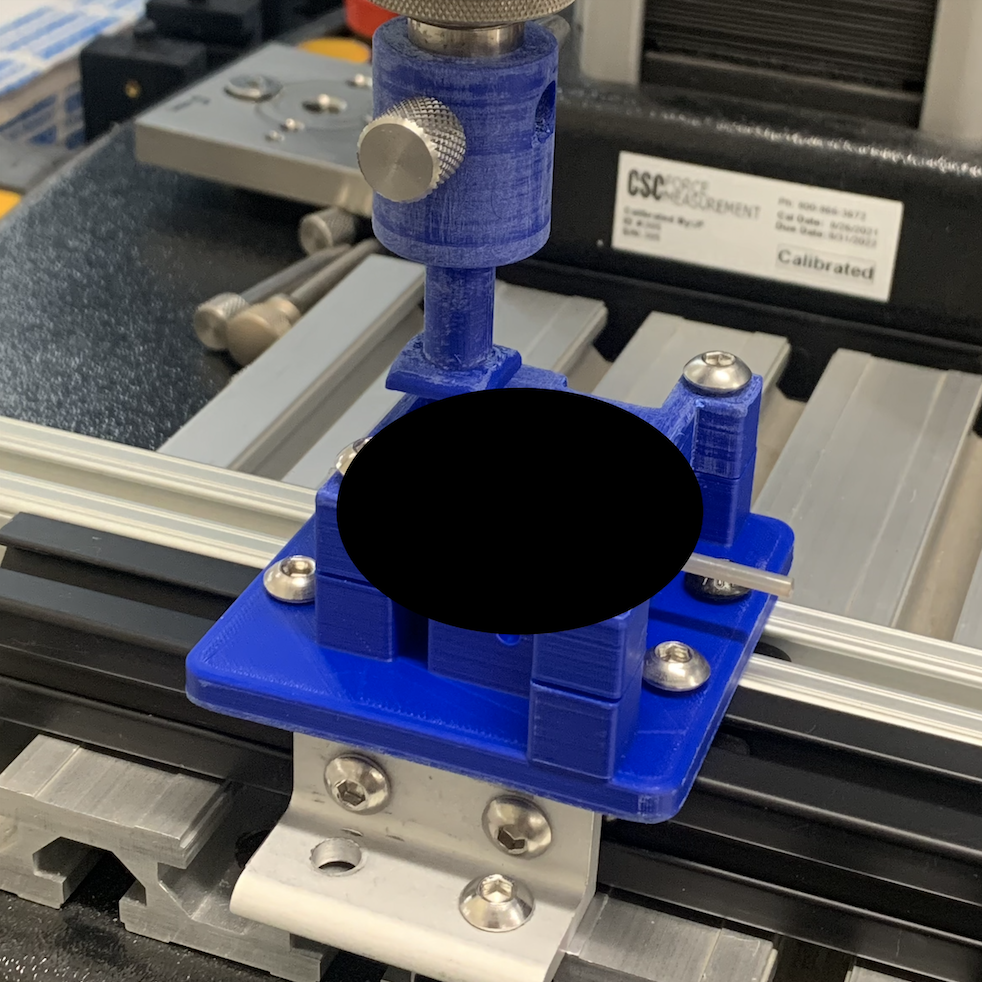

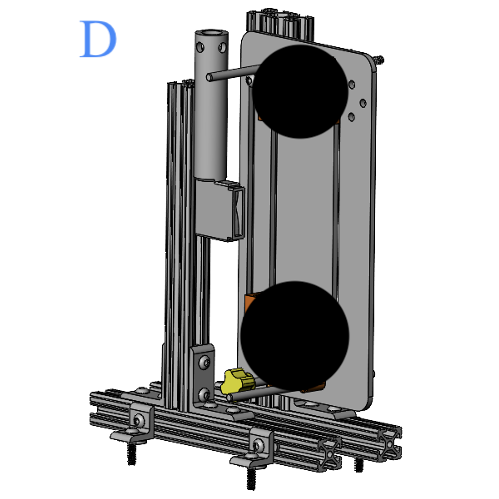

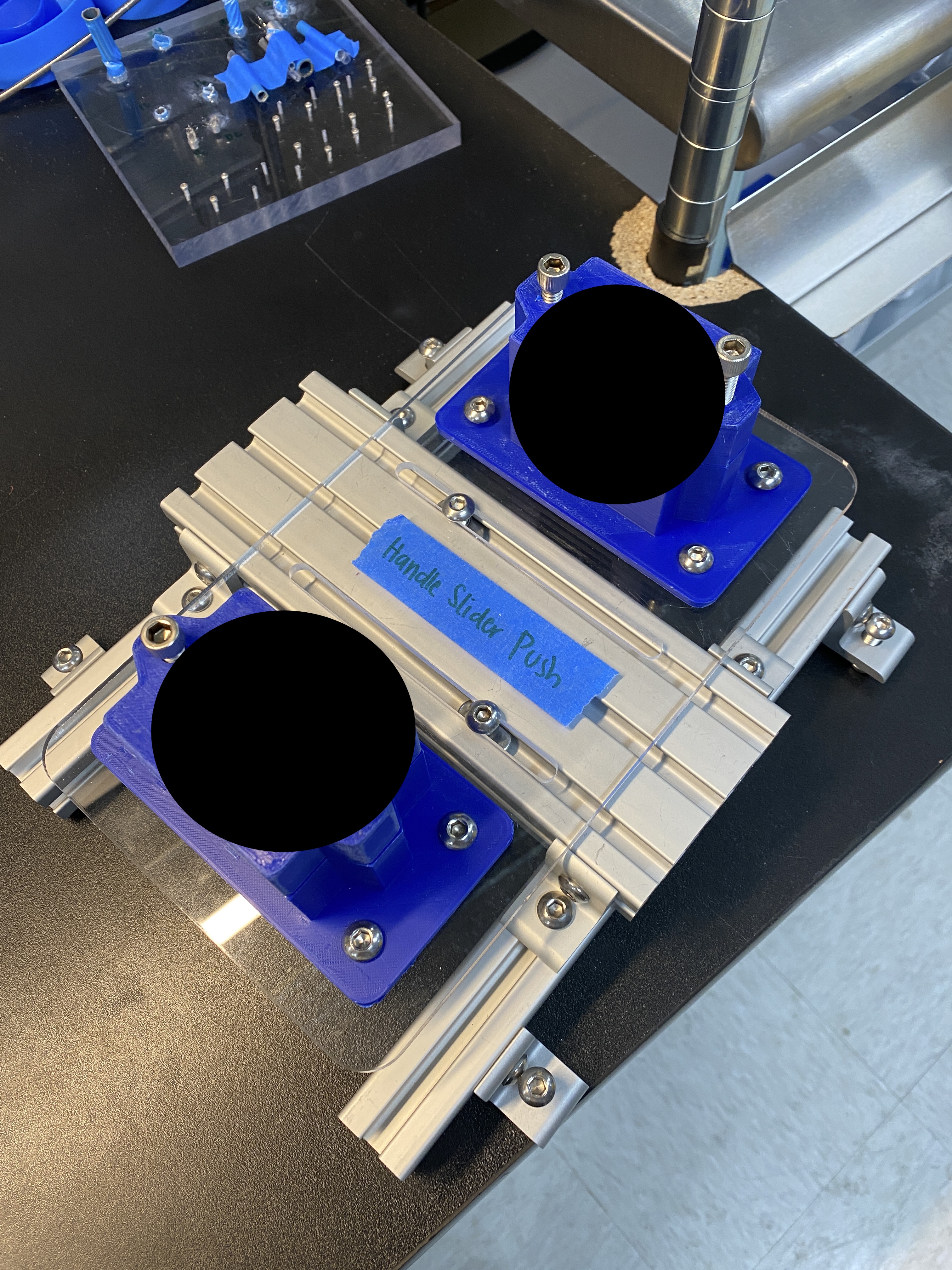

Figure 1. Fabricated Fixture for Pre-Design Verification Compression Force Testing