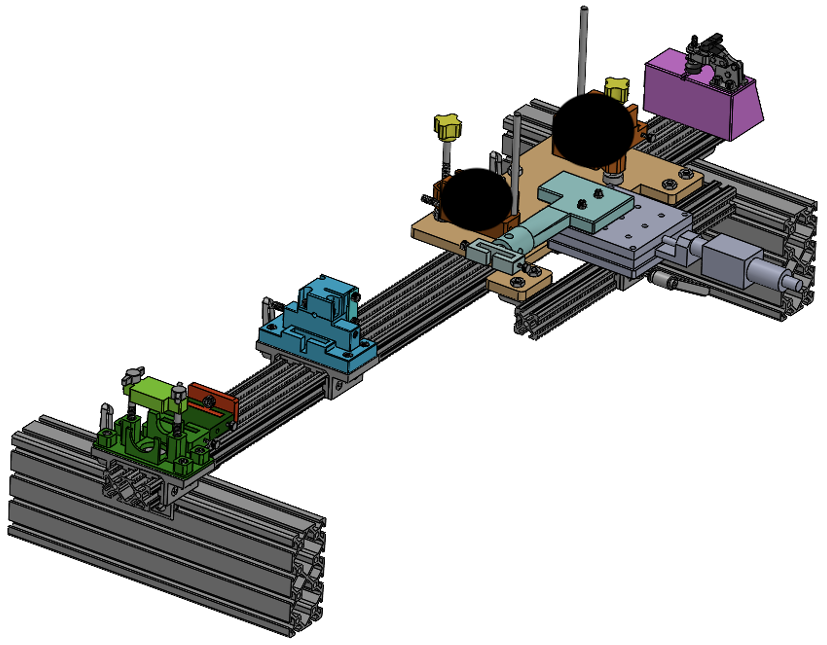

Problem

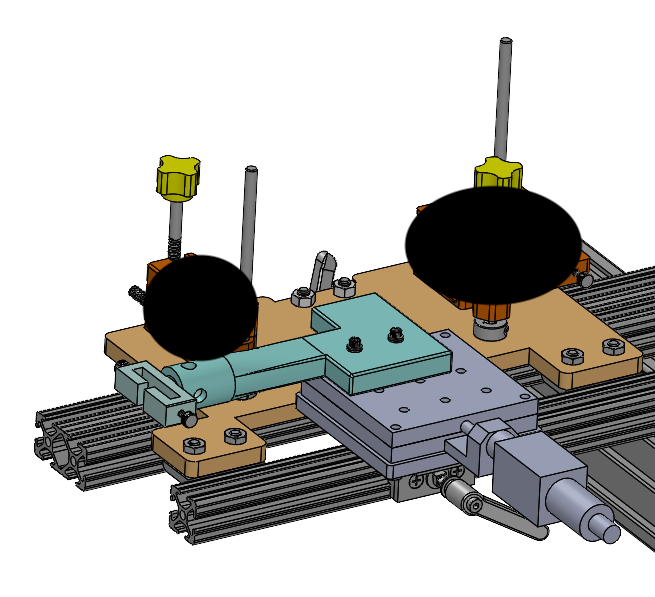

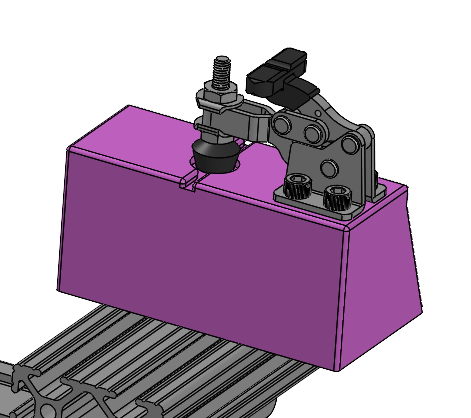

The company’s products required fixtures to stabilize and consistently mobilize each component during actuation and force measurements during a simulated use test.

Objective

To design and build fixtures that can securely hold and smoothly actuate each component during each step of the test.

Skills Employed

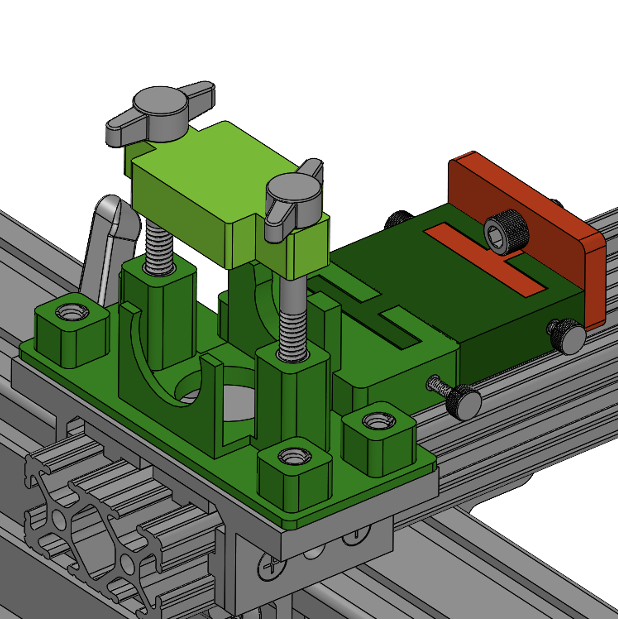

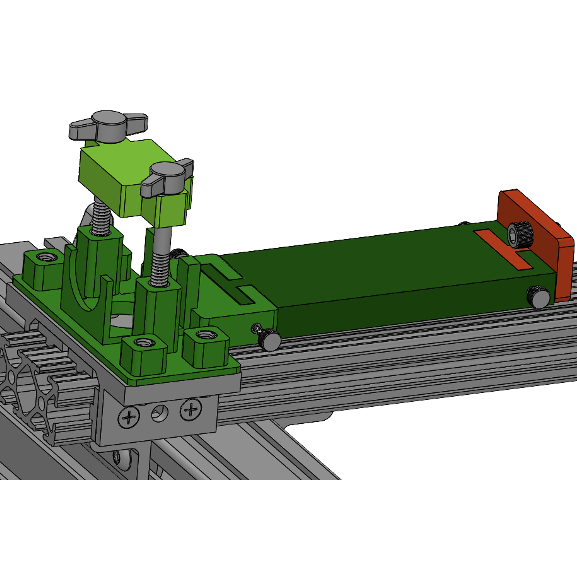

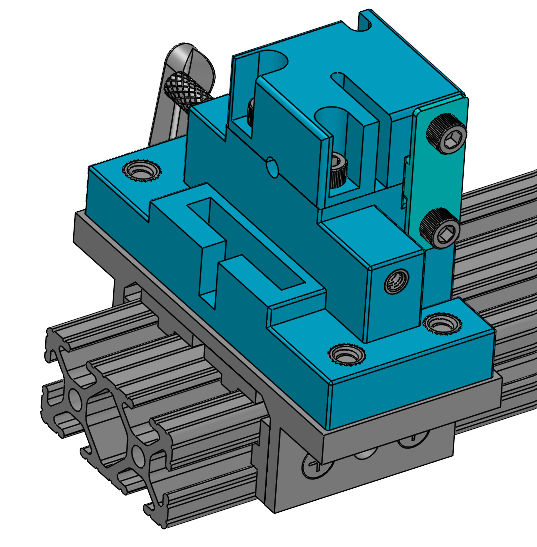

- SOLIDWORKS 3D CAD model and 2D drawings with tolerances

- 3D Printing FDM

- Laser Cutting

- Working with 80-20 rails, linear bearings, structural brackets, fasteners

- Snap-fits, cavity, and t-slot designs

- Machine shop manufacturing and tool use (chop saw, tapping, drills, sanding)

- Working with heat set and press fit inserts, ACME lead screws, thumbs screws, set screws, toggle clamps, micrometers

- Hand-held force gauge

- Testing fixture design/mechanical testing